sURFACE PREPARATION

SURFACE PREPARATION

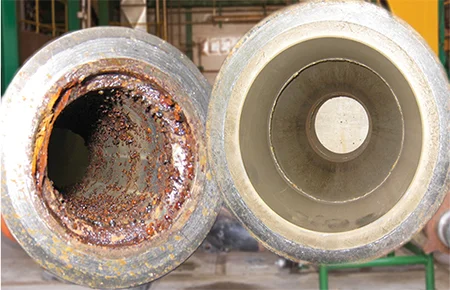

Surface preparation is the essential first stage treatment of a substrate before the application of any coating. The performance of a coating is significantly influenced by its ability to adhere properly to the substrate material. It is generally well established that correct surface preparation is the most important factor affecting the total success of surface treatment. The presence of even small amounts of surface contaminants, oil, grease, oxides etc. can physically impair and reduce coating adhesion to the substrate.

Methods of surface preparation:

- Chemical cleaning

- Tool cleaning(Hand Tool & Power Tool Cleaning )

- Combinational Pressure Water Cleaning

- Abrasive Blast Cleaning

Chemical cleaning

Metal equipment must be cleaned from time to time to prevent damage and maintain efficiency of operation. The chemical cleaning of metals has a number of advantages over mechanical cleaning methods. The greatest of these are that the metal equipment to be cleaned doesn’t need to be dismantled and reassembled, and the cleaning doesn’t damage the equipment, leaving areas that are more vulnerable to corrosion than before.

Hand and Power Tool Cleaning

Hand tool cleaning can be an ideal method to prepare small areas, areas with difficult access, or areas where the use of blast cleaning is not permitted or it is impractical. There are many different tools available to manually prepare surfaces; some of the most common include:

- Rotary wire brush

- Reciprocating impact tool (needle gun)

- Grinders or sanders

- Rotary impact or scarifying tools

Water Jetting

High Pressure (HP) and Ultra-High Pressure (UHP) water jetting are commonly used for the removal of coatings from steel structures in connection with maintenance painting. The suitability of HP or UHP should be considered carefully. Ideally a detailed site survey should be undertaken and specific site constraints established before work commences.

The equipment used in water jetting includes a high pressure pump unit, high pressure hoses, a jetting tool and sometimes a vacuum waste recovery system. Pumps used for commercial high pressure jetting operate up to 1700 bar (24,650 psi). Pumps for ultra-high pressure jetting operate at pressures greater than 1700 bar/24,650 psi.

Abrasive Blast Cleaning

Abrasive blast-cleaning is the common term for all methods using abrasives that are propelled toward the surface to be cleaned at very high speed. Typically this speed can be around 220 mph (350 km/h) on impact. This process produces a surface profile, the quality of which will influence the performance of any protective paint coating.

With high durability systems, it is essential to remove all mill scale and old coatings, as well as other contaminants, if the coating systems are to perform at their best.One advantage of blast cleaning is that it provides a surface profile (anchor pattern) that can be tailored to suit the coatings being used.